| Chosen Design Concept

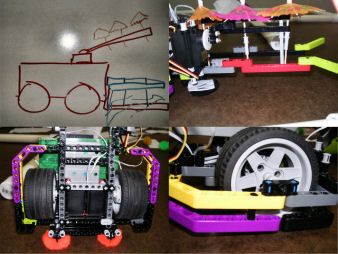

Bot 1

We have chosen a design with two black motors geared directly to the

wheels and a servo that holds/places the umbrellas. In addition, we have

a funnel to force the houses into a straight line and hold them there

when we put the umbrellas on them and then drive back to the starting

box. We also have decided to use two large touch sensors on the back of

the bot so we can align to the pipes. Because during various tests,

pineapples and leaves have interfered with the touch sensors, we placed

two flat panel fairings in front of the sensors. This way, even with

interfering composts, our sensors will still trigger at the proper

times. This bot should score a max of 24 points.

Bot 2

We decided to make robot 2 a stationary bot, but its construction is

slower than the other 2 robots. This could be a very helpful design

because there are very many ways to score points, since the house are

located at a workable distance from the starting box. Using retractable

arms, this robot will simple reach out and grab all the houses at once,

thus it will have 3 arms and 3 corresponding servos. The exact details

of the arms have just been worked out. The center arm will be a folding

arm, since the distance to the center house is the shortest. The other

two will be non-folding, but not entirely rigid. They will bend, and a

rubber band on each will provide some folding capability upon extension.

When those arms retract into an upward-pointing position, the weight of

the house will cause the farther half to fold down, which will help

bring all the houses in line with each other inside the starting box.

After each house if pulled in, a white motor places umbrellas on each

house. This bot should score a max of 24 points. We have not gotten to

the point at which we test and evaluate the consistency and efficiency

of this bot, although we have half completed it and have built some

prototype arms.

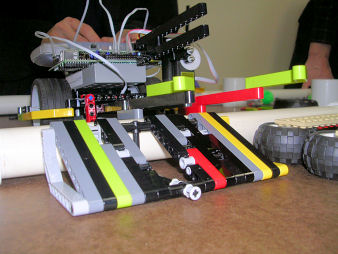

Bot 3

We have chosen a design that utilizes two black motors to drive and

steer. We also have decided on a servo to raise and lower the arm that

picks up and then deposits the water. On this arm we have mounted a

white motor to eject the water into the bins. We also use another servo

and arm combination to block the volcano. This arm will be hinged and

have a latch so that it can fit into the starting box. This bot will

have two large touch sensors on the back so that it can align to pipes.

The front of the bot will also have a large touch sensor so that the arm

that picks up the water will rise at the right point. We are also

planning on using an XBC with an SP game boy so that it does not

interfere with the arm that picks up the water. This bot should score a

max of 10 points, plus any lava that its arm can block and deflect to

the other side.

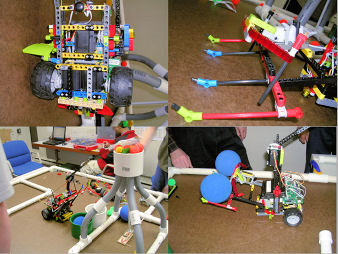

Bot 4

We evaluated many different methods of sorting the leaves and pineapples

and found sorting them mechanically difficult. Obviously this is the

most important feature of the robot, as aforementioned in earlier

reports, as of now. In considering possible mechanisms we evaluated some

designs used last year by other teams to solve the 'tribble'-sorting

problem, a problem that is very similar to this one. We have decided to

have one clamp, powered by a white motor, remain at the height of a

pineapple and grab and lift in into a bin, perhaps walled by paper. The

leaves will be swept into a side bin be a ground servo arm. These will

then be lowered/raised into the crop bins. In addition to this

mechanism, a movement plan must be worked out to get all the piles.

Lessons Learned from Simulation

Simulation Lessons for Bot 1 & 3:

Our group read the instructions and attempted to enter our code into the

robot simulator. However, we had difficulty executing the program. Our

simulator failed to accurately depict the movements of our robot which

we later tested in a game situation on the game board. Our results

included a square which moved out of the starting box and froze. These

unexpected results were probably due to the fact that the distance

values weren’t coordinated in the simulator. For example, when we

expected the robot to go forward 6 inches, it did not move a

corresponding distance in the simulation run. In addition to this, we do

not know how to set up the sensors in the simulator. Because all of our

robots use touch sensors to properly align, it became nearly impossible

to get accurate results from this simulator.

Simulation Lessons for Bot 2:

Two simulation tests were conducted on Robot 2. They both involved

building part of the robot with Legos and substituting another part of

the design with ordinary non-Lego parts. They are as follows:

The first simulation involved the determination of whether a folding

arms was feasible, given the distance of the house from the starting box

and the weight of the houses. The arms were first built with rubber

bands designed to trigger expansion of the whole arm. To simulate the

house, we attached a D-sized 1.5 volt battery at the end and used a

motor attached to string to determine if the arm could pull it up. It

turned out that it couldn't really, (which was kind of expected). The

string broke frequently and the rubber wore out. It was particularly

horrible for the left and right houses, which are at a considerably

greater distance away.

The next simulation involved the weight distribution and center of

gravity for the robot as a whole. We found that pulling up the houses

(substituted as batteries) brought the robot close to tipping out of the

box. We realized that using an XBC alone (although heavy) may not be

enough, so we decided to have more weight fill in the robot, which would

lower the center of gravity even more.

Simulation Lessons for Bot 4

No simulations have yet been done on this robot because it is still

being conceived/built.

Lessons Learned from Prototype

Prototyping was not

very hard to set up, so we tested concepts of the entire robot at once,

broken down by robot:

All:

One key item we learned was that in programming, use of the motor()

command and then waiting for a specified time was not very accurate. If

the robot's battery levels were only slightly different, the robot would

travel a different distance during a given time period, causing the

robot to do different things based on the level of the batteries. Use of

the mav() command in IC was better, but it still remained slightly

inaccurate when one motor went faster than the other. Finally, a

solution was reached using the mrp() command, which told the motor to

move a specified number of revolutions forward, making the distance

traveled the same each time regardless of the time taken. To compensate

for differing motor speeds, a subroutine was created that drove each

motor for the specified number of encoder counts. In this subroutine, a

small unit of power was subtracted from the fast motor, causing the

robot to run straight.

Bot 1:

This robot had major problems with driving straight, veering off to the

left after a few inches of driving. To fix the problem, code was added

to turn the robot slightly to the right during long runs down the board.

However, this is a temporary solution and will eventually be removed as

a good constant is found for equalizing motor power as described in the

previous section. Aligning with the walls also helped, since code could

be set up to turn the robot if only one side sensor was pressed down.

Tribbles could get in the way of the sensor, blocking the switch and

leaving the robot stuck at the wall with a sensor that would never

activate. Instead of solving this mechanically, our team chose to add a

time-out in the code, which assumed the robot was aligned to the wall

after three straight seconds of backing up with no touch sensors

pressed. The arm to place the umbrellas and funnel to collect the houses

worked as expected. Consistency is still an issue, but this robot is

well on its way. It can score the expected number of points, 24, during

most of its runs.

Bot 2:

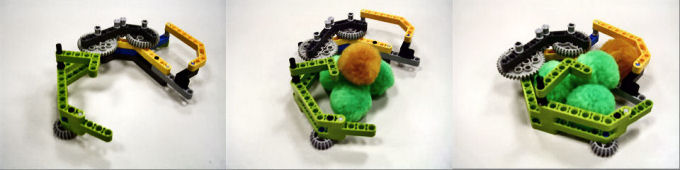

A few prototypes of this robot have been built, all of which are arm

prototypes, because after all, it is the most important feature. These

different prototypes represent different ways of retrieving the houses

and placing umbrellas on them.

The first prototype involved a rubber band triggered arm that unfolded

rapidly upon impact of the trigger against the side of the pipe (of the

starting box). Upon release, it would fall with its own weight, hit the

pipe, then unfold. A motor with string attached to it and the arm would

reel the whole thing in, allowing it to fold itself up compactly. First

of all, this prototype could not withstand the strain of a house's

weight on the end, and it did not properly fold all the time. We first

built this for the center arm, which is shortest. But the design was not

feasible for the longer arms, simply because of the greater distance and

the consequent increase in motor power needed. So this prototype was

abandoned. The next prototype involved having the all the arms rigid,

with no rubber bands. This theoretically would be easier to handle

because we could use the stronger servo to lift the arms. When we built

it, we found that a lot of torque (naturally) was required and it would

be a strain on the servos, although they could still do it. Also, the

arms resulted in an odd formation of houses brought back into the

starting box that it was difficult to place umbrellas on them.

After that, we built yet another prototype, this time using more beams

to aid in the folding process, with a servo to help extend and retract.

This, we found, was much better than the former two because the forces

to lift the weight were distributed in different angles and it was

overall easier to lift. Also the arm happened to be rather compact when

folded. However we couldn't quite use this prototype for the longer arms

because folded version was not compact at all and rather difficult to

extend. So we decided to only use that arm for the center, short arm.

Bot 3:

Unlike Bot 1, this robot had fewer navigation issues, requiring minimal

adjustment to run straight. Tribbles were still a problem when the robot

aligned with the pipes, but a mechanical guard was built over the sensor

to deflect tribbles away from the switches. The biggest changes for this

robot were in the manipulator system. First, the water manipulator was

tested. From the beginning, we expected to pick up the water from above.

However, this proved hard to build and we decided to push a scoop

underneath and pick up the water. This scoop required a servo in the

base to raise the arm up and down, but it did not require a grabber

motor unlike the initial idea. Our first shovel design attempt was

finicky, since it failed to hold onto the water after picking it up. A

second design was tried, this time with a bent piece on the end to hold

the water inside. Now there were problems with removing the water and

putting it inside the bins. After a few failed tries to make a passive

system for ejecting the water that would trigger when the robot impacted

the cans, a white motor was placed on the end of the arm to push the

water out when needed. In the code, this robot needed a loop to bring

the water arm up in increments with a pause in between, so the water

would not fly off the side of the board as the arm went up. A front

touch sensor was also incorporated so the arm could be raised at the

right point. But the biggest changes were yet to come when the volcano

lava blocker was tested. We had anticipated the problem of the long arm

fitting in the starting box, and placed a joint accordingly to allow the

arm to bend inside the box. A servo was also incorporated to flip the

blocker over the top of the robot and onto the volcano, However, when a

rubber band was placed on the joint to pull it into position after the

robot left home base, the joint was unable to resist the upward pressure

of the volcano and bent, causing the blocker to fall off and lava to go

everywhere. A latch was eventually designed to lock the arm into

straight after leaving the box. The blocker itself was to be made out of

paper, but our initial design used more than 36 square inches. After

designing a new, smaller attachment, the robot failed to consistently

hold the lava inside the volcano. Insight came one day when somebody

bothered to measure and found the arm too tall for the starting box. The

arm was promptly shortened to fit, but this had the unintended effect of

allowing the arm servo to bring the arm farther forward. Thus, the latch

worked much better and the arm did not move when the volcano was fired,

causing more lava to fall on the opponent's side, sometimes even 12

pieces to one on a good run. Therefore, this robot was able to score

more points than anticipated by causing the opponent to lose more points

while helping to eliminate negative points for our team.

Bot 4:

Not many prototypes of this robot have been built yet, however we have

built a small simple prototype of a mechanism to grab the pineapple off

of the pile of leaves. It involves a clamp of two halves, one half

rigid, the other powered and lowered by a white motor. Since the whole

structure will remain at this one height above the board, it is an ideal

solution to grab pineapples, which are conveniently placed above the

leaves. When the clamp clamps onto the pineapple, another white motor

will lift the whole thing up over the back of the robot and dump the

pineapple in its bin, to be walled with paper.

We figure that the rest of the leaves will be swept aside with a servo

arm into another bin. The difficulty lies in the attempt to raise and

lower those bins to the crop bin heights and dump all of them out,

without losing any. |